ZR-3260DA Intelligent Stack dust( gas) Tester

It adopts isokinetic sample and membrane filter (cartridge) weighing method to measure dust concentration while using electrochemistry or optical principle sensor to analyze O2, SO2, CO, NO, NO2, H2S, CO2. And also the velocity of flue gas, flue gas temperature, flue gas humidity, flue pressure and exhaust air rate etc.

Standards

EN13284-1

US EPA M5

US EPA M17

ISO 9096

Function and principle

> Dust sample—isokinetic sampling & gravimetric method

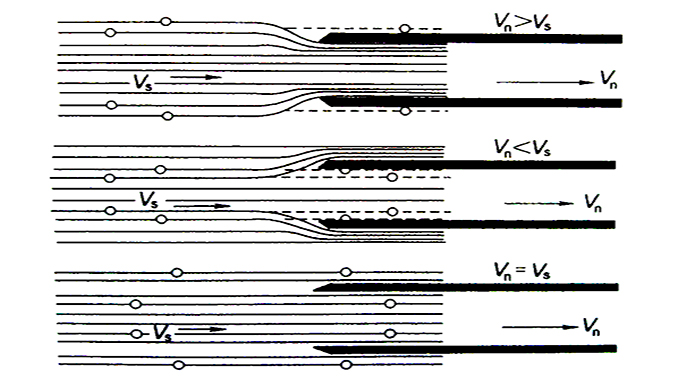

velocity of flue gas entering the sampling nozzle = velocity of flue gas at the sampling point

particulate matter has a certain mass, due to its own inertial motion in the flue, it cannot completely change direction with the airflow. In order to obtain representative dust samples from the flue, isokinetic sampling is required, that is, the velocity of gas entering the sampling nozzle should be equal to the velocity of the flue gas at the sampling point, and the relative error should be within 10%. The velocity of gas entering the sampling nozzle is greater than or less than the velocity of flue gas at the sampling point, which will cause deviation in the sampling results.

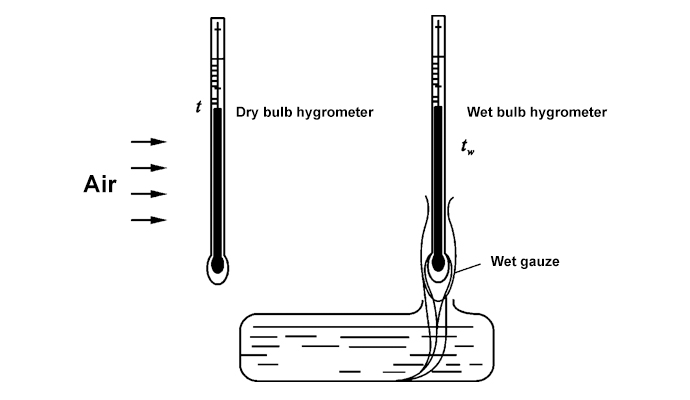

> Humidity—wet and dry ball

MPU controls sensors to measure wet ball,dry ball, wet ball surface pressure and exhausted static pressure.Combined with temperature of wet ball surface temperature to trace the related saturated vapor pressure--Pbv,calculates flue gas humidity in accordance with formula.

> O2 measurement

Put the sampling probe to extract flue gas with O2 and measure instant O2 content.According to O2 content, computes air excess coefficient α.

> Gas sample—Electrochemical Analysis /Fixed potential by electrolysis method

Put the sampling probe into the stack to extract flue gas including SO2,NOx.After dedusting and dehydration treatment,through SO2,NOx electrochemistry sensor,the following reaction will happen.

SO2+2H2O —> SO4- + 4H++2e-

NO +2H2O —> NO3- + 4H++3e-

Under certain conditions, the size of the sensor output current is proportional to the concentration of SO2, NO.According to the measurement of the sensor output current ,can be calculated instantaneous concentration of SO2, NOx.At the same time, according to the test flue gas emissions parameters, instruments t can calculates SO2 and NOx emissions.

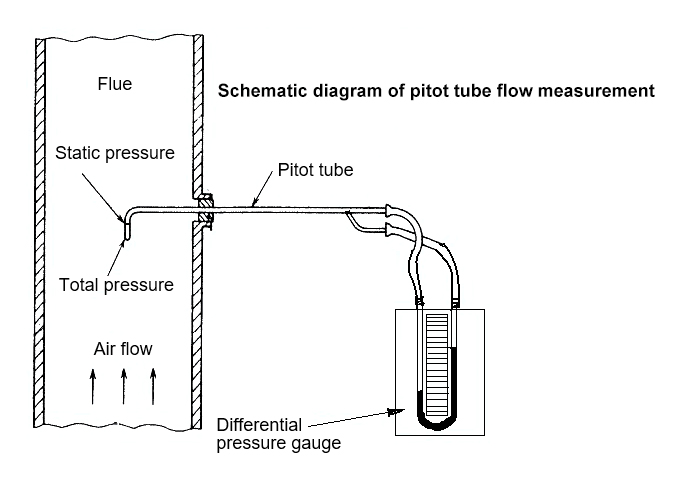

> Velocity of flow—Pitot tube method

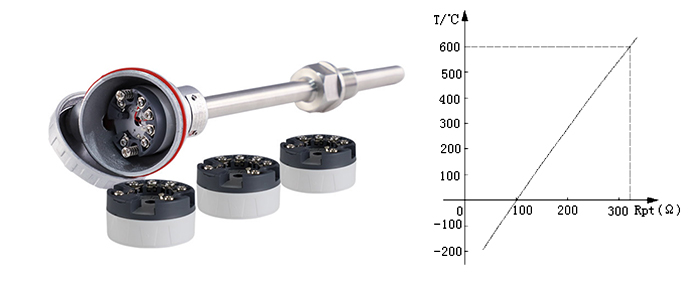

> Temperature in flue gas—PT100 method

Features

> Isokinetic tracking sampling,Rapid response.

> High-load, low-noise sampling pump.

> Strong stability of anti-static and anti-interference.

> Unique design of efficient gas-water separator with high efficiency of drying, improves silicone's use.

> Particular dustproof and waterproof keyboard, elaborately arranged as computer keyboard, easy to operate.

> 5.0 -inch color screen ,touch operation , wide working temperature , clear Visual in sunshine.

> Intelligent software calibrating function.

> small size, light weight, easy to operate, easy to carry.

> High capacity data storage, supporting U-disk data dump and data review.

> Adopt high speed miniature thermal printer, with high-speed and low-noise.

Deliver Goods

● All kinds of boilers, industrial furnaces

● Dust removal efficiency measurement

● Assessment and calibration for CEMS accuracy

● Waste incineration

Dust technical parameter

| Parameter | Range | Resolution | Error |

| Sampling flowrate | (0~110)L/min | 0.1L/min | ±2.5% |

| Flowrate control | ±2.0%(voltage change ±20%,resistance range:3kpa—6kpa) | ||

| Dynamic pressure | (0~2000)Pa | 1Pa | ±1.0%FS |

| Static pressure | (-30~30)kPa | 0.01kPa | ±1.0%FS |

| Total pressure | (-30~30)kPa | 0.01kPa | ±2.0%FS |

| Flowrate pre-meter pressure | (-60~0)kPa | 0.01kPa | ±1.0%FS |

| Flowrate pre-meter temperature | (-55~125)℃ | 0.1℃ | ±2.5℃ |

| Velocity range | (1~45)m/s | 0.1m/s | ±4.0% |

| Atmospheric pressure | (60~130)kPa | 0.1kPa | ±0.5kPa |

| Auto tracking Precision | —— | —— | ±3% |

| Max sampling volume | 99999.9L | 0.1L | ±2.5% |

| Isokinetic trackingresponse time | ≤10s | ||

| Load capacity of pump | ≥50L/min(when resistance is 30 PA) | ||

| Size | (L275×W170×H265)mm | ||

| Weight | About 6.8kg(battery include) | ||

| Noise | <65dB(A) | ||

| Power consumption | <300W | ||

Flue gas technical index

| Parameter | Range | Resolution | Error |

| Sampling flow | 1.0L/min | 0.1L/min | ±5% |

| O2(optional) | (0~30)% | 0.1% | Indication error:±5%Repeatability:≤1.5%Response time:≤90sStability:change within 1hExpected life:2 years in air (beside CO2) |

| SO2(optional) | (0~5700)mg/m3 Can extend to 14000mg/m³ | 1mg/m3 | |

| NO(optional) | (0~1300)mg/m3 Can extend to 6700mg/m³ | 1mg/m3 | |

| NO2(optional) | (0~200)mg/m3 Can extend to 2000mg/m³ | 1mg/m3 | |

| CO(optional) | (0~5000)mg/m3 Can extend to 25000mg/m³ | 1mg/m3 | |

| H2S(optional) | (0~300)mg/m3 Can extend to 1500mg/m³ | 1mg/m3 | |

| CO2(optional) | (0~20)% | 0.01% |