0102030405

Biological Safety Cabinet(BSC)Testing Solution

2024-03-15 10:31:06

What is Biological Safety Cabinet Testing?

BSC is a negative pressure filtration and exhaust equipment based on the principle of high-efficiency filtration and airflow dynamics. It will protect samples from external contamination and to better protect testing personnel from being infected by pathogenic microorganisms during operation.

Therefore, whether the performance of the BSC is stable not only related to the success or failure of the experiment, but also the safety of operators and medical staff. BSC are generally required to comply with that country or region's standards.

The equipments must be certified at least annually by qualified personnel, generally mechanical or electronic engineers who specialize in the maintenance and certification of this type of equipment.

Testing Items?

Air velocity within the work zone.

Air barrier testing (the barrier between operator and product; some standards utilize inward velocity testing instead)

Filter integrity (leak testing or the amount of aerosols that a filter allows to pass through it)

Particle counting within the work zone

Gas tightness

Leak testing of the work zone (work zone integrity testing)

Illuminance within the work zone

UV light effectiveness

Sound level, etc.

The requirements may be governed by an institutional body such as the TGA, FDA, or WHO.

What equipment is needed for a BSC calibration?

1, Particle Counters

According to the GMP/FDA’s guidelines, monitoring of sterile conditions must be performed at the same time to survive and cannot survive, and the handheld particles can be placed in the lower airflow of the BSC working area for detection.

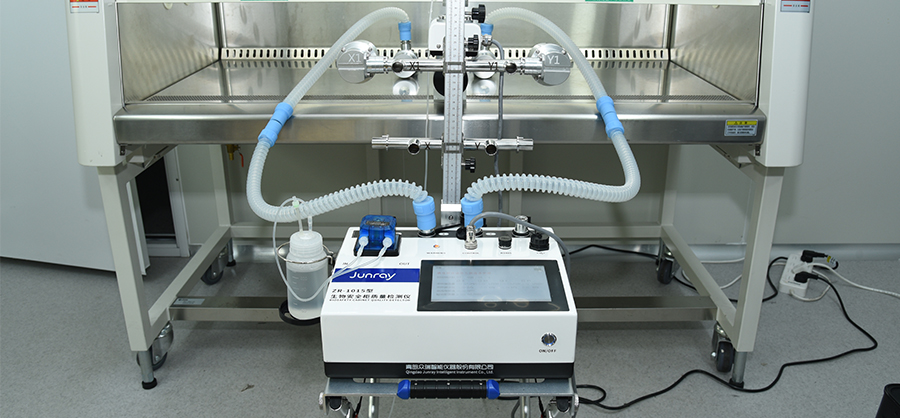

2, Filter Leakage Testers

This test determines the integrity of downflow and exhaust from HEPA filters, filter housings, and filter mounting frames. To carry out the test, the standard indicates the use of a calibrated photometer and a calibrated aerosol generator.

The test is based on knowing the exact concentration of the polydisperse aerosol upstream of the HEPA filter and detecting the penetration through the filter, mounting frames, and/or filter housing.

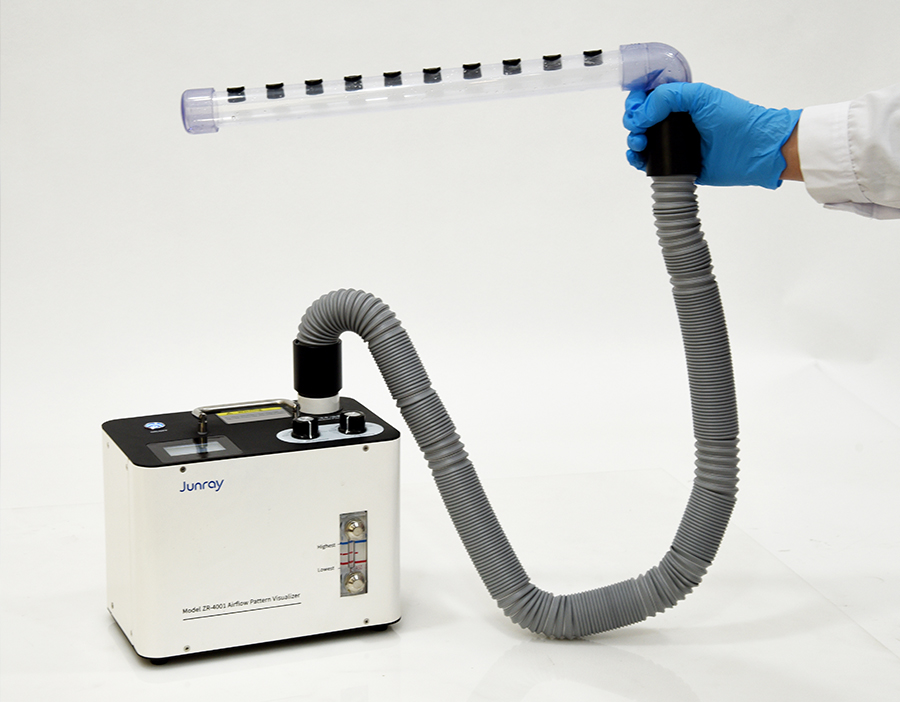

3, Airflow Pattern Visualizer(AFPV)

Good airflow organization can ensure rapid purification of pollution. To visualize airflow, the mist needs to occur to flow with the airflow. AFPV as an airflow visualizer for smoke studies to monitor patterns and turbulence.

4. KI Discussion Device

Background test, personnel protection, product protection and cross-contamination protection. It is mainly used to determine whether the aerosol in the cabinet leaks to the outside of the cabinet; whether external pollutants enter the biosafety cabinet; and whether the cross-contamination between products in the biosafety cabinet is minimized. Potassium iodide test method takes only 30 minutes, which will not pollute the laboratory environment.